LEED documentation can be finicky. Some manufacturers have great, easily accessible product information that is readily available on their website – with others it is like pulling teeth. For Materials Credits, this is critically important. Take MRc4 – Recycled Content. When a product data sheet gets to a LEED reviewer, they are looking for two critical pieces of information – clearly identified Post-Consumer and Pre-Consumer recycled content specific to that particular product. Not a range, not an average, not across a spectrum of products – but specific information for that particular product.

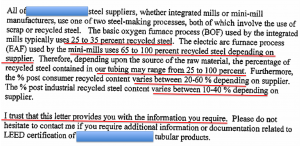

Here’s an example I see all too many times from manufacturers:

How’s that look to you? This manufacturer produces steel products that contain somewhere between 25-35% recycled steel OR 65-100%. A nice range between 25% all the way to 100%. Furthermore, it can vary between 20-60% post consumer and 10-40% preconsumer. Though, they trust this provides you with the information you require.

Yikes!

So…let’s say this steel cost $100,000. The amount that applies to LEED could be as low as $25,000 or up to $80,000 of compliant product. That’s a big gap!

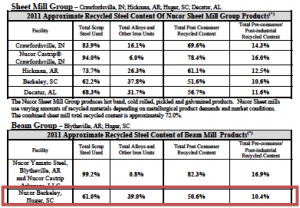

Compare that to the submittals from Nucor, and you’ll see quite a difference.

Notice how it is nicely laid out – this product comes from this plant with these exact pre and post-recycled contents. This is an example of LEED documentation that will fly through the review process.

So – make sure your subcontractors and suppliers are providing LEED submittals WITH their first submital AND make sure it very clearly shows you the specific product, the pre-consumer content, AND the post-consumer content, and you’ll be well on your way to successfully documenting your MRc4 credits.

This makes me laugh. That tubing company’s documentation has caused me issues.